As technology advances, we tend to pay more attention to the efficiency with which tasks, especially in business, are completed. Automatic tail sealing machines fully integrate tail sealing steps into high speed packaging systems to save even more time. This article will delve into the comprehensive sector, industrial, and general gains in productivity productivity these machines provide, while further categorizing them into more precise benefits with regard to each machine feature.

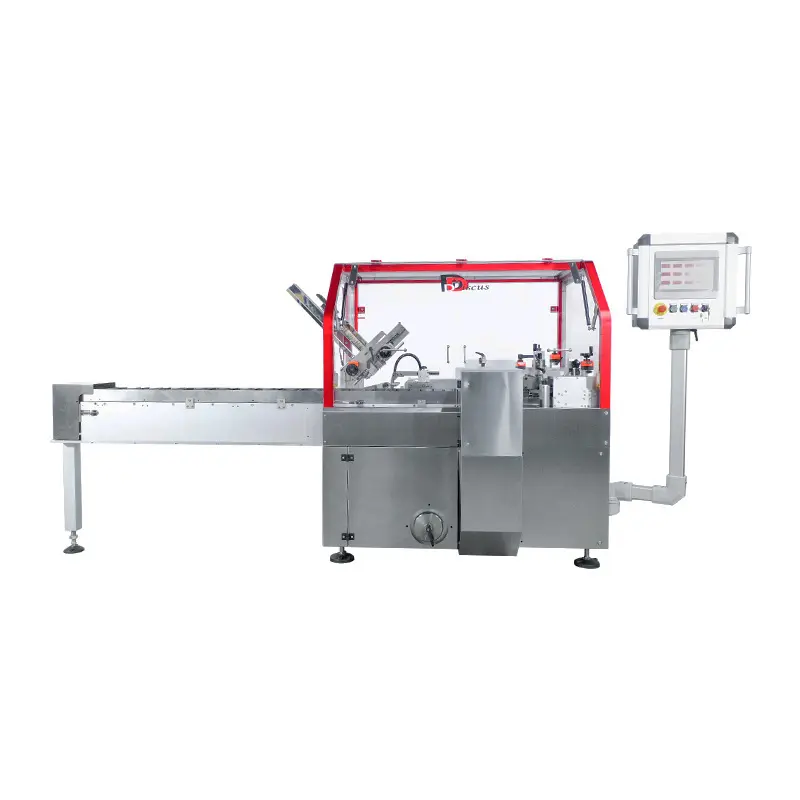

The goal of any automatic tail sealing machine is to aid with the tail sealing step of the packing process. Just like any other step in the manufacturing process, tail sealing has become much easier due to modern technology in form of automation. Fully automatic tail sealing machines allow the separation of the worker from the process, thereby reducing employee dependency. This boosts productivity. These machines have advanced sensor and control systems that guarantee precise tail sealing, which in turn improves profits while drastically reducing losses due to damage during shipment and storage in the highly competitive market that makes it imperative for businesses to balance profit against loss.

From cardboard to plastic and paper, the machines can accommodate various types of packaging. It is the fully automatic tail sealing machines that take the cup because of their flexibility and ability to cater to more than one customer. The variety of food products further guarantees business to new customers coming from other industries like pharmaceuticals and consumer goods. These machines provide customizability that allows these new customers to effectively increase their operational business productivity, consequently meeting their new customers' needs and expectations.

Moreover, these machines possess remarkable operational rates. They seal hundreds of packages each minute, saving invaluable production time. This output is essential for companies considering growth in business and for those geared towards achieving consumer satisfaction. For manufacturers attempting to strengthen their position in the market, the ability of the fully automatic tail sealing machine to perform at high speeds without compromising quality is highly beneficial.

Sustainability is one of the most remarkable advantages of these machines. They are designed to save on the use of the sealing materials and also reduce wastage during sealing. A fully automatic tail sealing machine will be of interest to businesses trying to lower their carbon footprint because it helps to achieve sustainability and efficiency goals.

In conclusion, one of the most critical machinery in high-speed packaging processes is the fully automatic tail sealing machine. It improves operational efficiency, works with different kinds of materials, and meets sustainability goals all at the same time which turns out to be a smart investment. As new industries shift technology and changed their operation practices, there is expected to be a rising need for these types of innovative solutions.

Shift in trends and the market: More businesses are adopting fully automatic systems, which is making the growth rate of automaton packaging systems in the industry grow at an unprecedented rate. Tail sealing machines are also expected to have more advanced functionalities like AI and ML which increase overall operational efficiency while decreasing the downtime. In addition, there is expected to be more innovations aimed at improving waste and energy minimization in packaging operations due to the increased focus of sustainable development.